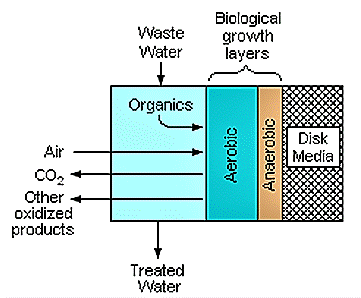

Effluents from RBC do not contain high levels of nutrients and are therefore not particularly interesting for agriculture, although they constitute a source of water. However, due to reduce removal of microorganisms, RBC effluents require a further treatment, such as sand filtration, constructed wetlands or another form of disinfection (e.g. chemical disinfection or UV disinfection).

Effective parameters in wastewater treatment:

• Media surface area

• Quality of the inlet wastewater

• Wastewater volume

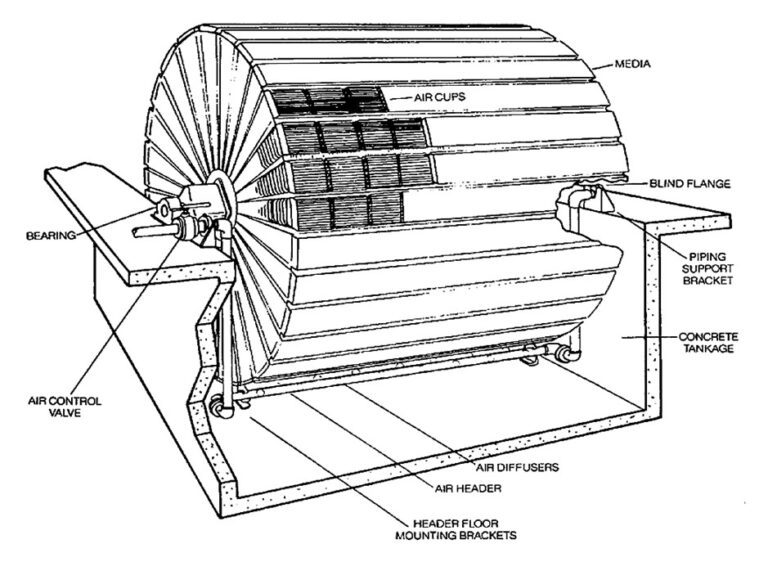

Organic loading is the primary design parameter for the RBC process. Wastewater temperatures above 55°F have a minimal effect on organic removal and nitrification rates so the various correction factors that must be utilized to determine the needed additional media surface area.

In determining design-loading rates on RBCs, the following parameters should be utilized:

• Design flow rates and primary wastewater constituents

• Total influent BOD5 concentration

• Soluble influent BOD5 concentration and percentage of total and soluble BOD5 to be removed

• Wastewater temperature

• Primary effluent dissolved oxygen

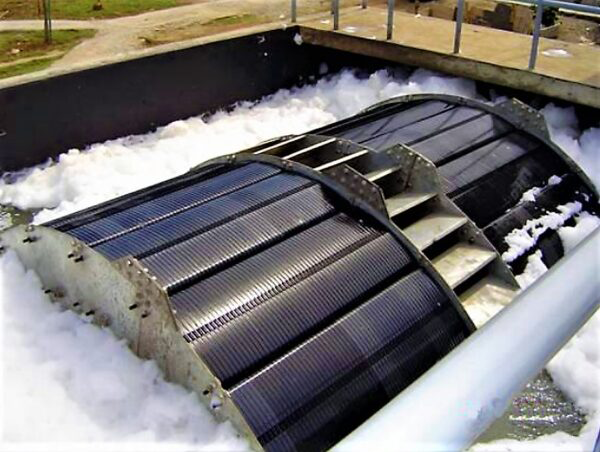

• Media arrangement, number of stages, and surface area of media in each stage

• Rotational velocity of the media

• Retention time within the RBC tank(s)

• Influent soluble BOD5 to the RBC system, including soluble BOD5 from in-plant side-streams, septage dumps, etc.

• Influent hydrogen sulfide concentrations

• Peak loading, BOD5 max/BOD5 avg

Advantages:

• Stable performance

• Lower costs due to modular construction and reduced excavation

• Longer retention time requires less space

• Minimal system overflow

• Low energy consumption

• the only maintenance required is simple lubrication

• Reduce costs compared to suspended growth systems

• Simple operation, no recycling flow, less laboratory testing for process control

• Low sludge production

Disadvantages:

• It has less efficiency than conventional activated sludge process

• Must be protected against sunlight, wind and rain (especially against freezing in cold climates)

• Requires permanent skilled technical labor for operation and maintenance

• Removes a small amount of the pathogen.

Applications

• Municipal wastewater treatment

• Food and Beverage Wastewater Treatment

• Garbage leachate

• Refinery and petrochemical wastewater treatment plant

• Pulp and paper wastewater treatment

• Lagoon washing water