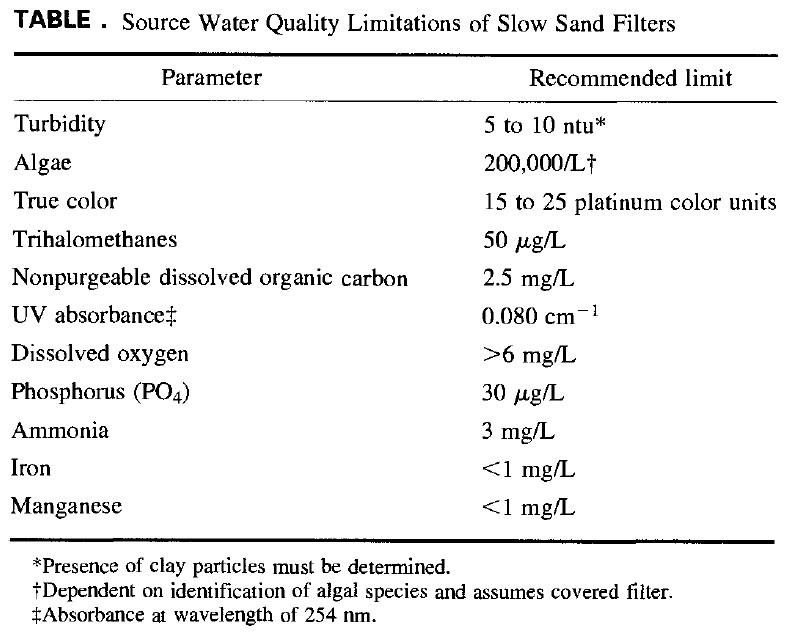

Turbidity:

Both the level and type of turbidity in source water must be considered. In general, most existing slow sand plants successfully treat source water turbidity of less than 10 NTU, which is recommended for an upper limit in designing new facilities. Also of some importance is the stability of the water. Slow sand facilities operate more efficiently if source turbidity is relatively constant and generally –< 5.0 ntu. Of equal importance is the nature of particulates. Source waters that normally contain clay particulates or that pick up clay after storm events will cause problems for slow sand filters. This difficulty for slow sand filters occurs because clay penetrates deep into the bed or may even carry through the filter, causing an immediate problem of elevated filtered water turbidity and a long-term problem of filter clogging and reduced length of filter runs.

Algae:

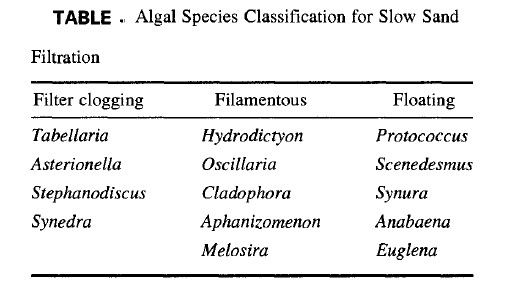

In a few instances, it has been found that the presence of certain types of algae actually enhances the filtration process by providing greater surface area for biological activity. In general, however, the presence of algae in the source water reduces filter run lengths. Table 9.2 presents a list of commonly found algal species, divided into categories related to their effect on filter performance . Filter-clogging species are detrimental to filter performance, while filamentous species may actually enhance

filter performance by providing greater surface area. Floating species would not result in direct clogging of the filter, but may shorten run lengths based on poorer-quality raw water.

Algae may be present in source water delivered to the filter and may also occur in an uncovered filter bed open to sunlight. In general, it is prudent to reduce algal content in source water to as low a level as possible to limit its effect on filter performance. Observation of algal growths, as well as identification, will aid with assessing the need for pretreatment, such as copper sulfate, and in determining when filter run lengths may be shortened. Some researchers have suggested the measurement of chlorophyll at concentrations

of 5 mg/m 3 as a limit in source water .

Color:

Color in treated water is currently categorized by USEPA as a secondary contaminant in drinking water supplies, with the focus being aesthetic concerns. As identified by Christman and Oglesby (1971), the yellow to brown color of many source waters can be the result of microbial breakdown of lignins from woody plants. True color removals of 25% or less were reported by Cleasby et al. (1984). Other research has indicated a removal range between 15% and 20% for total organic carbon. When one is evaluating the applicability of slow sand filtration for a specific source water, a review of historical trihalomethane (THM) data can reveal whether the expected low removal efficiency of aquatic organic substances by the process is a concern. Where historical color and THM data are unavailable, a sampling program can be initiated to aid in evaluating whether slow sand filtration is an appropriate treatment method.

Iron and Manganese. Slow sand filters remove iron and manganese through precipitation on the sand surface in a scaling-like action, but an upper limit of 1 mg/L of iron is suggested to avoid forming an iron precipitate that could clog filters. A similar limit for manganese would also appear to be acceptable. Collins et al. (1989) showed that iron precipitate on a slow sand filter enhanced the removal of organic precursors.

Dissolved Oxygen. The presence of dissolved oxygen in source water is critical for stimulating a healthy schmutzdecke for proper slow sand filter operation. Some slow sand plants use aeration of the water as a pretreatment. Reduction of dissolved oxygen levels commonly occurs following algal blooms, so that the importance of dissolved oxygen in the source water is another reason to control algal growth in the source. Potential problems resulting from dissolved oxygen deficiencies include tastes and odors, redissolving of precipitated metals, aesthetics, and increased chlorine demand .

Nutrients:

The proper operation of the schmutzdecke is somewhat dependent on the presence of sufficient concentrations of carbon, nitrogen, phosphorus, and sulfur. Carbon and sulfur (in sulfate form) are prevalent in most source waters. However, protected reservoir systems may have limited concentrations of nitrogen and phosphorus present.

It has been reported that, for every 1 mg of carbon removed by the schmutzdecke, 0.04 mg of nitrogen and 6/xg of phosphorus are required (Skeat, 1961). Slow sand filters have also shown the ability to remove up to 3 mg/L of ammonia from source water under the right conditions. Ammonia can be used as a source of nitrogen for the filter.

Effluent Water Quality

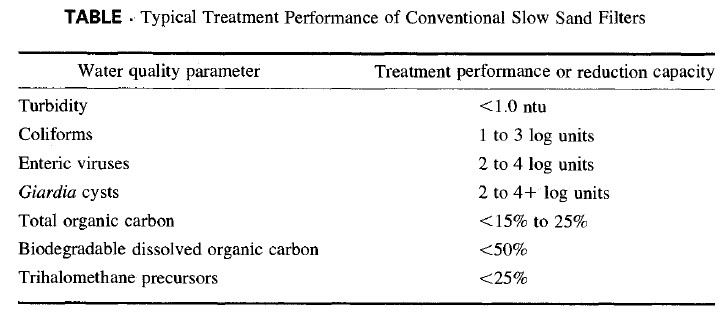

Slow sand filtration has been shown to be effective in achieving removal of Giardia and viruses. Effluent turbidities in the range of 0.1 to 0.2 ntu are typical for high-quality source waters, while turbidities of up to 1.0 ntu may be considered an upper limit. Removal of organic substances is generally in the range of 15% to 25%. Recent research has focused on improving removal because of disinfection by-product formation considerations.

Typical treatment performance of conventional slow sand filtration plants is listed in below Table Current regulations require effluent turbidities of less than 1.0 ntu. Pilot testing of the source water is recommended for determining the operational parameters and possible need for supplemental treatment to meet the established turbidity requirements. Limited data are available on removal capabilities with respect to Cryptosporidium, but research is continuing.