- Home

- Major projects

- Processes

WATER TREATMENT

- CHLORINATION

- ELECTRODEIONIZATION (EDI)

- ULTRAVIOLET (UV) DISINFECTION FOR WATER TREATMENT

- ULTRAFILTRATION (UF)

- SLOW SAND AND DIATOMACEOUS EARTH FILTRATION

- REVERSE OSMOSIS (RO)

- MICROFILTRATION (MF)

- RAPID GRANULAR BED FILTRATION

- Nanofiltration (NF)

- OZONE DISINFECTION

- PRESSURE SAND FILTERS

- MIXED BED ION EXCHANGE (IX)

- GRANULAR ACTIVATED CARBON FILTER

- ION EXCHANGE RESIN WATER SOFTENER

- MEDIA FILTRATION

WATER TREATMENT

- Moving Bed Biofilm Reactor (MBBR)

- Upflow Sludge Blanket Filtration (USBF)

- Sequencing batch reactor (SBR)

- Rotating Biological Contactor (RBC)

- DISSOLVED AIR FLOTATION (DAF)

- Conventional Activated Sludge (CAS)

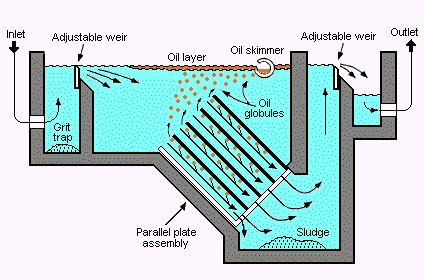

- API (American Petroleum Institute)

- Membrane bioreactor (MBR)

- Intermittently Decanted Extended Aeration (IDEA)

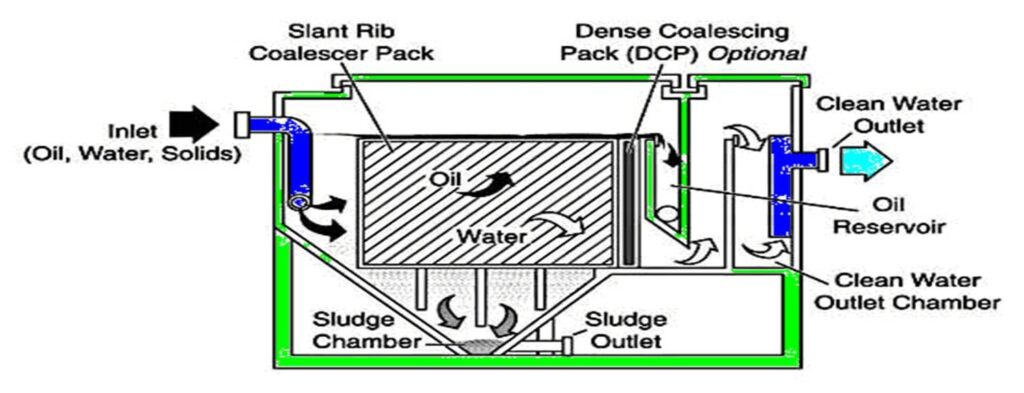

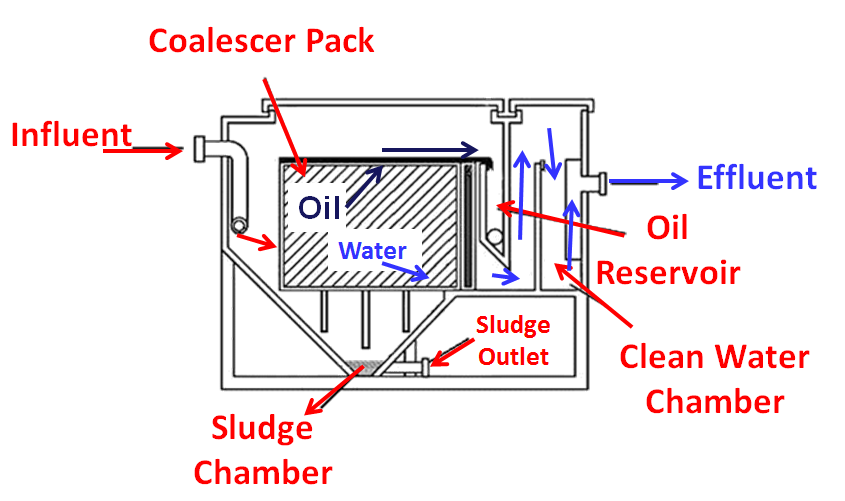

- CPI (Corrugated Plate Interceptors)

- Integrated Fixed Film Activated Sludge (IFAS)

- Extended Aeration Activated Sludge (EAAS)

- Equipment supply

- About us

- Contact us